Integrated Package Solutions

Flare Gas Metering & Monitoring Solutions

We have solutions for Flared or Vented Gas Measurement using latest state-of-the-art technology Ultra-Sonic Measurement from leading OEMs; with our value-addition in design/selection of metering products of different OEMs and fabrication of spool assembly, to satisfy technical compliance to regulation & customer specification and techno-commercial value creation with optimized prices & delivery schedule:

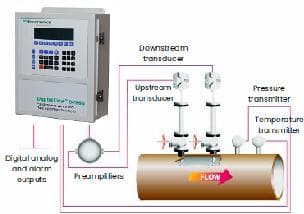

- Flare Gas Flow Computer

- Ultrasonic Transducers

- Pipe Spool for Transducers (single or dual path)

Often subject to taxation and strict regulations, the accurate measurement of flare gas has a variety of benefits that go beyond avoiding over-taxation on emissions or liability to penalties. Knowing how much gas is flared or vented allows you to reduce emissions. This data can also generate revenue by selling the gas or create savings through onsite re-use.

In addition, the wealth of data received lets you check for mass-balance calculation irregularities, thus identifying potential leaks before they pose a risk to health and safety. With zero flaring being the focus of international regulations and NGO initiatives, managing your flare gas emissions is not only industry best practice, but puts you at the forefront of a more sustainable way to use natural resources.

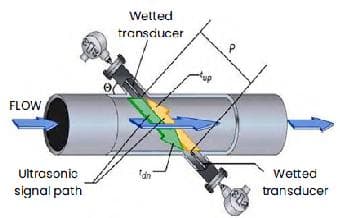

Unlike other technologies, ultrasonic measurement is not impacted by the composition or cleanliness of the gas flow. It delivers good repeatability regardless of turndown ratio or temperature ranges. In fact, ultrasonic meters do not need shutdowns for installation or maintenance.

Solution A

- Standard Accuracy with Single Path - Two Probes

- High Accuracy with Dual Path - Four Probes

- Flare Gas Meter, Compliance to: Ex de [ia] IIC T6, Tamb: -40 °C to + 60 °C ATEX: Nemko 07ATEX1160 and IECEx: NEM 09.0009X

- USM probes – Complaint to: Ex ia IIC T2-T4 (Zone 0) IP66; Ex ia IIC T4-T6 (Zone 0); -94 to+293 °F (Std); -166 to 392 °F (Opt)

- Pipe size (Single Path): 2" to 72“ (Std); 74" to 82" (Opt)

- Pipe size (Dual Path): 12" to 72“ (Std); 2” to 12” & 74" to 82" (Opt)

- Velocities up to 400 ft/s

- 4000 to 1 turndown Ratio

- Measures velocity, mass & volume flow rates,

- Density and Molecular weight.

- Wetted Non-Intrusive Sensors/ Probes

- No pressure drop

- No maintenance/ No Moving Parts.

- Certified for Operations in Hazardous Areas (Zone-0).

Solution B

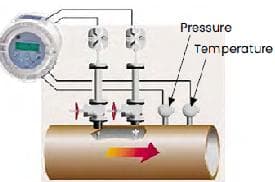

- Measures velocity, volumetric and mass flow

- Measures Net Heating Value (NHV) of Vent Gas in BTU/SCF, MJ/m3, or KJ/m3

- Independent of Gas composition; No Pressure drop

- Measures Instantaneous Average Molecular Weight

- Standard Velocity Range: 100 m/s (328 ft/s)

- Extended Velocity Range: 120 m/s (394 ft/s)

- Accurate low flow rate measurement

- 4000 to 1 turndown ratio

- Single or Dual Path Transducer Configurations –40°F to 140°F (–40°C to 60°C)

- Allows Cross Flow Immunity in Large Pipes

- Minimal Maintenance, As No Moving Parts, No Holes or Tubes, Tolerance to Dirty or Wet conditions and Easy serviceability

- Field-proven installation techniques