Integrated Package Solutions

High Integrity Pressure Protection Systems (HIPPS)

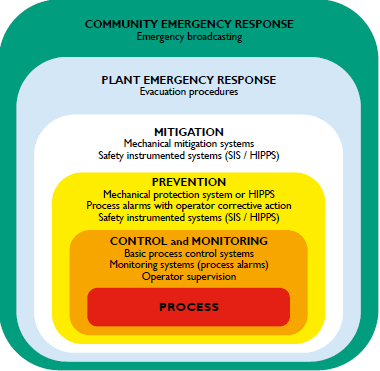

We have fully Integrated “HIPPS (High Integrity Pressure Protection System) or IOPSS (Instrumented Overpressure Safety System)” to prevent over-pressure from hydrocarbon source (Wellhead/ Reservoir) by shutting-off the source of the high pressure. In traditional systems over-pressure is dealt with relief of venting systems. These systems have obvious disadvantages such as release of (flammable and toxic) process fluids in the environment and often a large footprint of the installation. With the increasing environmental awareness relief systems are no longer an acceptable solution.

HIPPS/ IOPSS provides integrated and cost effective solution to protect equipment in cases where:

- High-pressures and / or flow rates are processed

- The environment is to be protected.

- The economic viability of a development needs improvement

- The risk profile of the plant must be reduced

What is HIPPS or IOPSS?

HIPPS or IOPSS that closes the source of over-pressure within 02 seconds, it avoids emissions to atmosphere and provide a “GREEN” alternative to Flare or vent systems.

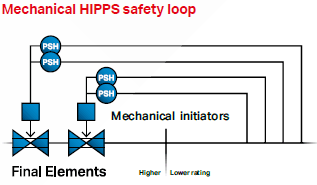

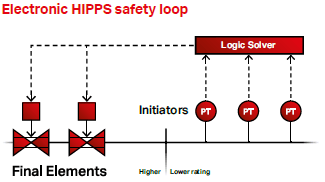

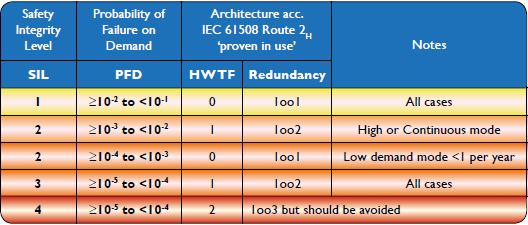

The HIPPS/ IOPSS is designed and built in accordance with the IEC-61508 and IEC-61511 standards or the API14C standard. The HIPPS/ IOPSS can be electronic or mechanical and may even be stand-alone without requiring external energy source.

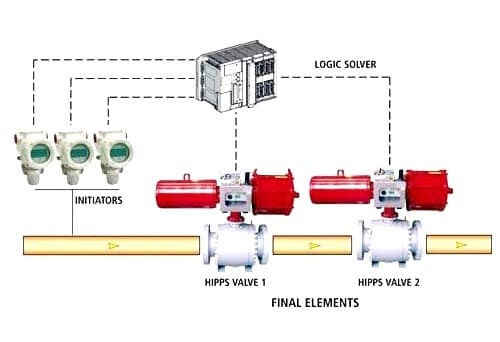

A HIPPS/ IOPSS is a Complete Functional Loop consisting of:

- The initiators that detect the high pressure, these can be electronic (PTs with HIMBs or mechanical (Pressure Switches)

- In electronic HIPPS/ IOPSS there is a logic solver, which processes the inputs from the initiators to an output to the final elements (fast Shutdown SDV x2)

- The final elements (SDVs), that actually perform the corrective actions by safe shut down of the process. The final element consists of Valve + Hydraulics/ Pneumatic Actuator x2 with Fire Proofing, SOVs, Valve position feedback switches and partial stroke testing (PST) device.

- Solar Power with Battery Storage & Inverter and Hydraulic Power Unit for SDV Actuator (as site specific option).

Advantages of HIPPS:

- HIPPS can protect personnel, environment and equipment incases where:

- High pressures occur and / or high flow rates are processed.

- The economic viability of a field development needs to be improved.

- Emission are to be reduced or avoided (e.g. toxic fluids).

Interested in HIPPS/ IOPSS? Contact us to take advantage of our bellow unique value-add:

We are single point of contact for the supply of complete integrated HIPPS/ IOPSS package. We select final and initiating elements of HIPPS/IOPSS from proven OEMs following customer AVL, than evaluate and apply the Certified TÜV Rheinland failure rates (available on www.certipedia.com) in accordance to project specification, from basic design at bidding stage till detailed design during execution of project. Our certified Functional Safety Engineers perform the integration of the complete SIS loop.

As required by IEC-61508 and IEC-61511 our Functional Safety Management System (FSM) is third party certified, to have SIS components SC3 certified. The field proven failure rates for both clean and unclean fluids are all from safety applications with 2 seconds stroking time.

We have dedicated team of engineers & technicians, fully equipped engineering facility to serve the Oil & Gas customers in MEA region; our design, engineering, assembly & testing facilities are in India & UAE and Sales & Service agents in all major MEA countries.

Our core philosophy for HIPPS/ IOPSS solutions reflects a partnership approach with below mentioned OEMs, to adapt and comply with customer specifications, AVL, FDS, and local & international codes & standards:

- CAMERON, LCM, MIR, RMT, SAMSON and Viar Valvole etc. for Shutdown Valves.

- BIFFI, DVG, IMI/STI, LEDEEN and Rotork etc. for SDV Actuator (Hydraulic or Pneumatic).

- BIFOLD, Dynatorque, DVG and Fischer etc. for PVST , SOV and other Actuator’s accessories.

- INDRA and ASTAVA for High Integrity Manifold Blocks - 2OO3 logic (Pressure TX) configuration.

- ABB, Emerson, Honeywell, Yokogawa and WIKA etc. for Pressure TX Switches and other field instruments.

- ABB, Honeywell, Rockwell and Siemens etc. for SIL-2 or SIL-3 Logic Solver using Safety System HW & SW.

- BILCO for Passive Fire Proofing of SDV Actuators.

- FTV Proclad (Dubai) and STS Clad (RAK) for Weld Overlay (Cladding) on Pipe Spools & Flanges.

- Metal Fab, Al-Bahar Engineering and FABTech for Skid Fabrication, Assembly and i-FAT facilities.

- Risknowlogy (UAE/ Germany) for SIL Audit and Certification of Complete Integrated HIPPS/ IOPSS Package.

- We can supply SIL-2 or SIL-3 Logic Solver using Safety System HW & SW from affiliated partners (OEMs), with Industrial Laptop “Engineering Station” and door mounted “Matrix/HMI display” in IP54 (for shelter installation) or IP66 (for field installation) enclosure. As per site specific requirement Solar Panels with battery storage & Inverter and Hydraulic Power Unit for SDV Actuator can also added in offered package.

- Our design of HIPPS/ IOPSS Package generally have provision for interface with Plant DCS/ ICSS/ SCADA, Asset Maintenance & Management, ERP and IOT/ Digitalization systems to meet current & future needs of customer.

Values you get

- Availability of HSE and QA/QC records for complete life cycle of project execution.

- Single source accountability for design, procurement, fabrication, assembly, integrated testing and on-site services for installation, commissioning & training.

- Modular Design to adapt/swap components in accordance to customer approved FDS and optimize prices & delivery time

- Customer review/approval during complete life cycle of project from basic design, till site installation and commissioning.

- Complete Functional testing during shop testing/ integrated FAT to optimize installation & commissioning time line.

- Assurance for quality technical support during asset life for spares, services and upgrade/retrofit.