Process & Industrial Automation Solutions

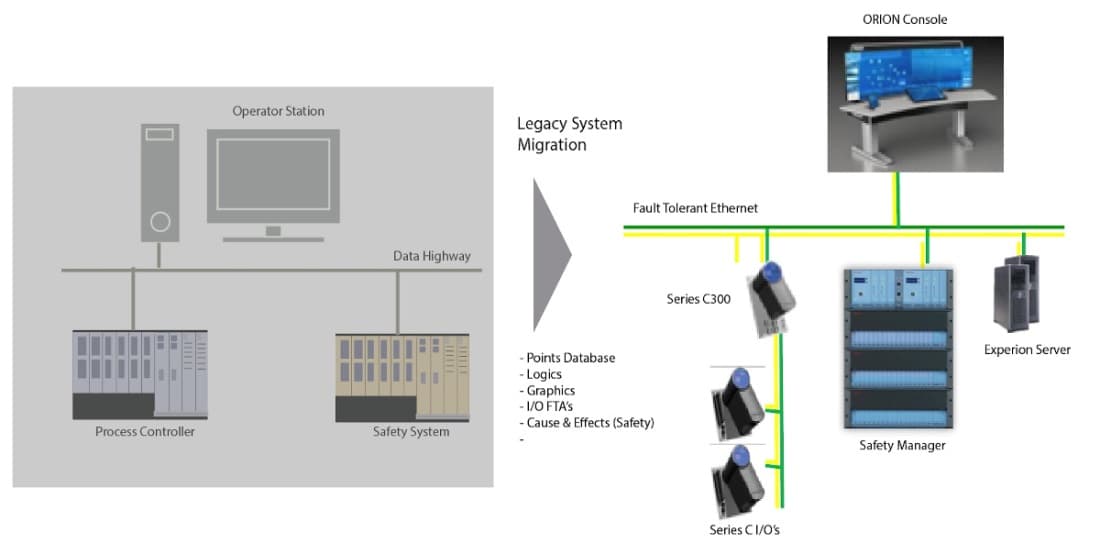

Automation Systems (PLC/RTU, DCS/SCADA, ESD/F&G etc.) Upgrade or Retrofit/ Migration with Expansion needs

Know when to migrate or upgrade your Automation Systems (PLC/RTU, DCS/SCADA, ESD/F&G etc.):

We provide unbiased consultancy services to mitigate the risk of OBSOLESENCE for automation systems, based on our vast and diversified working experience on different automation systems; it’s the DNA of our business to develop long term working relationship with our customers to create sustainable long term OPEX and CAPEX benefits.

There’s a big difference b/w a Phased Automation Systems migration and just delaying the problem of Automation Systems obsolescence. Those who do not plan for automation systems obsolescence will see options narrowed with passage time. At worst, obsolescence leads to higher costs as plants mitigate the rising risk of downtime or compliance failures hence, it may jeopardize continued and safe operations.

Obsolescence in the automation systems is a significant risk, if not managed properly. Aging automation system hardware (i.e. network/communication modules, PLC/RTU & I/O modules); software for HMI/SCADA & engineering station and most commonly computer hardware & operating system bring a whole host of problems. These include, but are not limited to, difficulty in sourcing spares, lead time for delivery and rising prices for them, increasing maintenance costs, declining reliability, capacity constraints, and a skills gap.

Upon completion of detailed study of existing system; operation & maintenance data/ challenges and several round of detailed meetings with O&M responsible team, we provide recommendation for System Upgrade to OEM offering or Retrofit/ Migration to new OEM and technology with consideration of future expansion needs, remaining asset life and ROI (with re-use of existing system engineering configuration and hardware & software components, plus following key benefits:

- Unbiased recommendation of Automation System partner, not just a product, with detailed technical specification.

- Overall cost to adapt system upgrade or retrofit/ migration to new OEM and technology, including O&M trainings and availability of needed spares, services and 3rd party components at economic price for best system life span.

- Massive strides in control technology and the benefits this can bring in terms of operator performance, SIL rated safety, compliance to IEC-61131, IEC-61508 and IEC-61511 efficiency, cyber security, enhanced functionality and system capacity.

- With migration or retrofit to a modern system can integrate control, safety and auxiliary systems, and benefit from enhanced control and visualization.

- Address the new business opportunities, expand capacity, and make use of new applications and solutions for advanced process control, asset management and production management.

We have expertise and references of Automation Systems (PLC/RTU, DCS/SCADA, ESD/F&G etc.) Retrofit/ Migration and Upgrade with Expansion needs in following industry sectors:

- Oil & Gas Pipeline, Petrochemical Plants and Refineries.

- Water Desalination and Power Generation & Distribution

- Water Transmission & Distribution Pumping Stations.

- Solid Waste & Sewage Water Treatment Plants and District Cooling Plants

- Renewable Energy i.e. Solar PV/CSP and Wind Energy

Key Features

- When selecting a automation system vendor, we select a partner for technology and retrofit/migration.

- Upgrading legacy HMI/ SCADA technology shall allows plants to have a common user interface to the integrated system architecture.

- When automation system requires change or expansion, we recommend to replace or upgrade the existing Controller/PLC/RTU with economic sense, keeping in mind that existing field signals must be quickly moved to the new Controller/PLC/RTU, and the existing control schemes must be migrated — and preferably improved.

- For a large-scale automation system retrofit or migration, we recommend a phased migration, it does have its drawbacks, but it is a lower risk approach with less downtime.

- The technology of automation system alone is not deciding factor for the success of migration or retrofit; the tools available for migrating, experience of engineers and migration plan & philosophy plays a vital role in determining how smoothly a system migration job can be executed, and how well disruption to operations can be minimized.