Process & Industrial Automation Solutions

Condition Monitoring Solutions for Rotating Machines

Our team has been providing highly-reliable machinery vibration monitoring solutions, that improves quality of monitoring, accuracy and precision to asset safety and protection of industrial machines and rotating equipment in Process Industries, Oil & Gas and Utilities sectors.

We offer broad product line from leading OEMs i.e. ABB, Rockwell and PVTVM as complete condition monitoring solution for every application such as:

- Monitoring high-value critical machinery,

- Portable vibration data collectors for routine predictive maintenance

- Easy-to-use vibration analysis software for balance of plant equipment.

Our offered condition monitoring solutions are independent of OEMs or Brands, as we select required products based on customer budget, AVL, safety & protection levels, compliance to codes & standards i.e. API-670, CE/CSA/ATEX/ TR-CU, NEMA, IP rating etc. life cycle of asset, future expansions and latest trends of technology i.e. Profibus, HART, Modbus, OPC, MS SQL, Cloud based Apps, Cyber Security, IIOT, Digitalization, Asset Management and ERP integration.

Offered Condition Monitoring Products & Solutions are from leading OEMs, assembled & tested for quality and intended functionalities at OEM facilities in EU/USA, China or India:

- ABB – Condition Monitoring for Motors, Pumps, Bearing & Gears, Power Trains and General Machinery

- ABB Ability™ Smart Sensor for Rotating Machines in Hazardous Areas

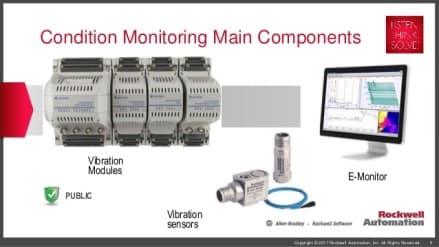

- Rockwell - Dynamix 1444 Integrated Condition Monitoring System

- Rockwell - 1441 Dynamix 2500 Portable Data Collectors

- PVTVM - PCM360 & PCM 370 Condition Management System

- PVTVM - PCM360-M Mobile Plant Condition Management System

- PVTVM - PT2060 Multi- Channel Rack Monitor and DTM Proximity Distributed Transmitter Monitors

- PVTVM – Vibration Sensors and Switches

Our Condition Monitoring Products and Solutions offering covers a wide range industries:

- Process Industries i.e. Oil & Gas, Petrochemicals and Refineries

- Utilities i.e. Power Generation and Water Desalination, Transmission & Distribution

- Infrastructure Assets i.e. HVAC, District Cooling, Fans etc.

- Cement, Sugar and Paper & Pulp Industries..

- Solid Waste and Sewage Water Treatment.

Key Features

- Complete plant rotating assets coverage –Motors, Pumps, Bearing/Gears, Compressors and Turbines

- Compatible with most sensors and probes, regardless of manufacturer

- Redundancy provision for relays, power supplies, analog outputs and communications modules

- Integration provision in Plant DCS/ ICSS/ SCADA/ AMS using Modbus, OPC, HART or Remote I/O.

- Up to 48 channels per rack, IP65, NEMA 4X environmental rating

- Unique proximity field linearization for any manufacturers’ probe and extension cable combination

- Works with all standard sensors: accelerometers, velocity, proximity probes (with or without probe driver)

- Wide temperature range: -50° C to +120° C

- CE approved and CSA and ATEX and TR CU certified for use in Hazardous Areas

- Maximum flexibility and expandability of the software system with object oriented modular design

- Built on Microsoft® SQL database to assure better data management and reliable networking

- Advanced post-processing of transient data minimizes data loss, maximizing analysis capability