Process & Industrial Automation Solutions

Distributed Control System (DCS)

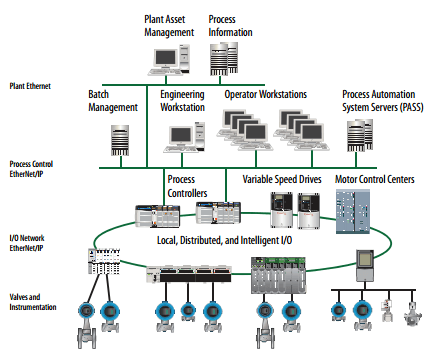

We have proven history of delivering dependable, cost-effective distributed control systems (DCS) across a broad range of industries covering Process Industries, Infrastructure, Oil & Gas and Utilities sectors. Our integrated DCS system will improve the reliability and productivity of your process operations with advanced analytics. We offer multiple communication links to facilitate easy integration with your existing equipment or 3rd Party Packages. Our DCS is scalable from low device count applications up to fully integrated plant-wide systems with more than 10,000 devices.

Our design/engineering and service team provides customers with dependable local support in MEA region, to ensure timely economic services during entire life cycle of project i.e. installation, commissioning, startups, system training, warranty and post warranty as well.

Our offered integrated DCS solutions are independent of OEMs or Brands, as we select DCS products based on customer budget, AVL, technical needs, life cycle of asset, future expansions or enhancements and latest trends of technology i.e. FF, HART, Profibus, OPC, Modbus , Cyber security, IIOT, Asset Management, Digitalization and ERP integration.

Our DCS solution design, control system products from leading OEMs, enclosures & housing and accessories are assembled and tested for quality and intended functions at modern integration facilities in Middle East – this enable customer to be part of review/approval cycle remotely or in-person and obtain desired customized functionalities in cost affective manner.

Our design and engineering team is fully familiar and trained on DCS product lines of major OEMs, to adapt the intended functionalities in DCS solutions as per customer needs of process automation:

- ABB - 800xA, Symphony+ and Freelance;.

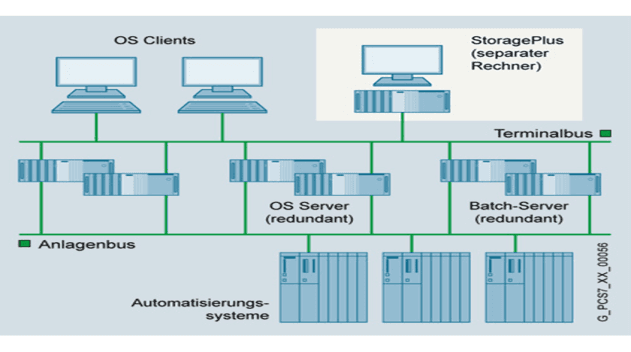

- Siemens - PCS 7

- Honeywell - Plant Cruise

- Rockwell - Plant PAX

We have expertise and references of DCS solutions in following industry sectors:

- Oil & Gas Processing, Petrochemical Plants and Refineries.

- Water Desalination and Power Generation.

- Water Transmission & Distribution Pumping Stations.

- Solid Waste and Sewage Water Treatment Plants.

- Renewable Solar PV/CSP and Wind Energy

Key Features

- We recognize and address the customer pain-points and challenges i.e. complex licenses packed with additional fees, unnecessarily complicated user interfaces making learning the system onerous, costly system shutdowns for module replacements, among others.

- Our DCS solution improves asset visibility, provides built-in troubleshooting and maintenance tools, offers simplified expansion capabilities, and reduces overall installation and training costs.

- Our redundant I/O communication and Power Supply design, enables independent module replacement without a total system shutdown.

- A three-level system network and server-client architecture provides real-time performance with high-speed data exchange where you need it most – between the controller and HMI.

- Built-in short term process data Historian (configurable up to 90 days) in Process Connectivity Servers, eliminate the needs of separate data Historian servers for less critical process/ plant applications.

- Provision to integrate 3rd party industry proven Historian i.e. OSI-Soft PI for complex process/ plant applications.

- Provision to add High Fidelity Dynamic Simulation of DCS package for cost affective on-job training of plant O&M team and simulation of process changes prior to implementation.