Process & Industrial Automation Solutions

PLC, RTU and Local HMI for Wellhead Control Panel

Our offering for Wellhead PLC has generally following features to adapt customer needs:

- Generally SIL-2 certified PLC as per IEC-61508,

- 10-15” local HMI with compliance to hazardous lass and ATEX

- All PLC hardware & accessories are ISA 71.04 level G3 protected.

- Sized so as to allow a correct thermal dissipation

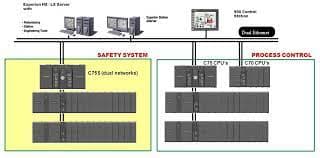

- Redundant CPUs, PSUs and Communication modules

- Non Redundant Analog I/Os with HART pass through capabilities for integration in AMS

- Digital input I/Os with line monitoring.

- Galvanic Isolators and SIL-2 Safety Relays

- Ruggedized industrial laptop with 04 hours battery, OEM software of PLC/RTU and latest configuration backups.

- Powered by 24v DC from Solar Power System,

- Capable to withstand the ambient temperature of +60 oC.

- Comply WHCP specification for Instrument cabling and glands.

- With Modbus RTU interface provision to a RTU on separate mounting plate (for integration in WHCP).

- Housed in IP-65 or above enclosure OR on a mounting plate for integration in WHCP.

Our offering for Wellhead RTU has generally following features to adapt customer needs:

- 7-10” local HMI with compliance to hazardous lass and ATEX (optional)

- Embedded HART, Modbus, DNP3 – No specialized modules required

- Embedded Cyber Security – Reduced Cyber threats. ISA Secure Compliant

- Redundant Controller – Improved reliability, not an engineered solution

- Integrated HART and Wireless I/Os improves device diagnostics, improves process uptime and reduces capital cost.

- Lowest power consumption of 1.9W with HART I/Os, enable savings with smaller solar panels & batteries.

- Enhanced cyber-security with embedded firewall and secure protocols for redundant controller.

- Integrated flow computing for liquid and gas meter runs with support for AGA algorithms and API compliance.

- Exceeds Harsh Environment Specifications: -40ºC to 75ºC and Conformal Coating – G3.

- Easy device add-on on brownfield sites with legacy & new protocols inline with Industry 4.0 requirements.

Our offered PLC and RTU solutions for WHCP are independent of OEMs or Brands, as we select PLC & RTU products based on customer budget, AVL, technical needs, life cycle of asset, future expansions or enhancements and latest trends of technology i.e. HART, Modbus, DNP 3.0, API library, Radio communication, Cyber Security, IIOT, Digitalization and ERP integration.

Our WHCP-PLC/RTU solution design , PLC/RTU products from approved OEMs, enclosures & housing and accessories are assembled and tested for quality and intended functions at modern integration facilities in Middle East or India – this enable customer to be part of review/approval cycle remotely or in-person and obtain desired customized functionalities in cost affective manner.

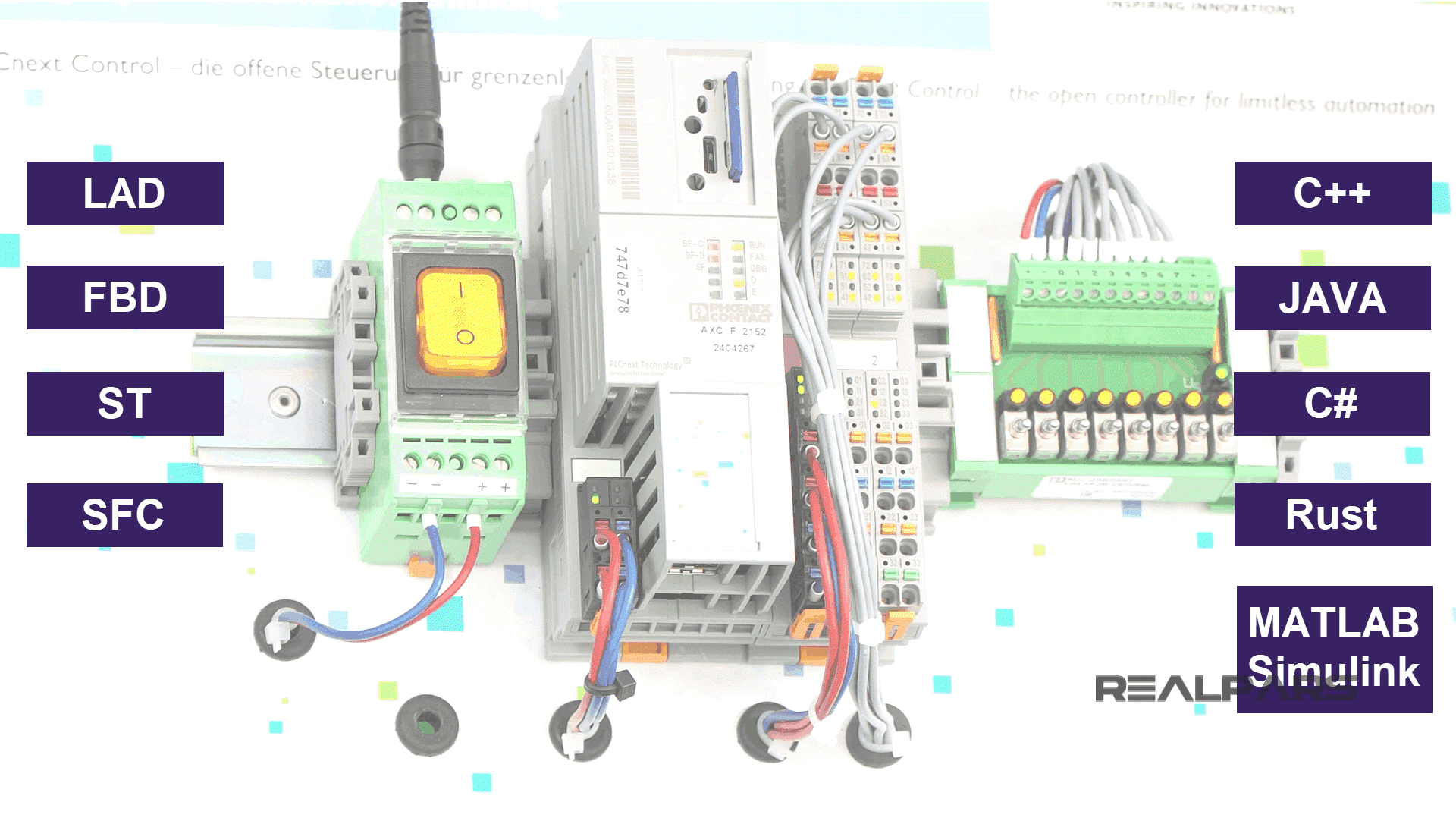

Our design and engineering team is fully familiar and trained on PLC/RTU product lines of approved OEMs and Industry standard configuration of IEC-61131, SIL-2, IEC-61508, to adapt the intended functionalities in WHCP-PLC/RTU solutions as per customer needs:

- Honeywell – Control Edge RTU2020, SIL-2 HC900 PLC and HCiX Touch Panel (HMI)

- Schneider – SCADA Pack Series RTUs

- ABB AC500-S Safety PLC and Process Panel (HMI)

- Rockwell – Compact Logix 5000 and Smart Guard 600 Safety PLCs

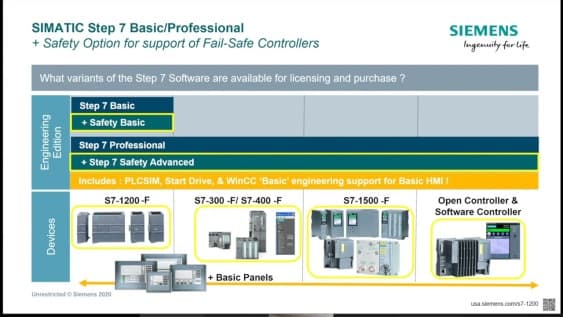

- Siemens – S7-1500F, S7-1200F SIL-2 PLCs and Simatic Comfort Panel (HMI)

- Beijer Electronics - QTERM Touch Panels