Process & Industrial Automation Solutions

Programmable Logic Controllers (PLC)

Our Programmable Logic Controller (PLC) packages are designed/ selected carefully:

- To reduce the integration costs for intended process and its operation & maintenance as well.

- To minimize the downtime through unified support,

- To decreases the risk with embedded Cyber security, and

- To lower the total cost of ownership through extended system lifecycle.

- To increase quality, accuracy and precision to industrial processes,

Our offered PLC solutions are independent of OEMs or Brands, as we select DCS products based on customer budget, AVL, technical needs, life cycle of asset, future expansions or enhancements and latest trends of technology i.e. Profibus, OPC, Modbus, Cyber security, IIOT, Digitalization, Asset Management and ERP integration.

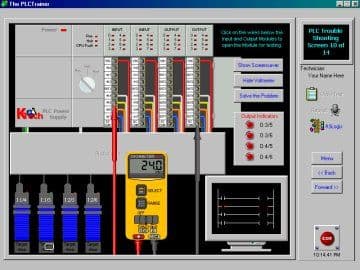

Our PLC solution design, PLC products from leading OEMs, enclosures & housing and accessories are assembled and tested for quality and intended functions at modern integration facilities in Middle East or India – this enable customer to be part of review/approval cycle remotely or in-person and obtain desired customized functionalities in cost affective manner.

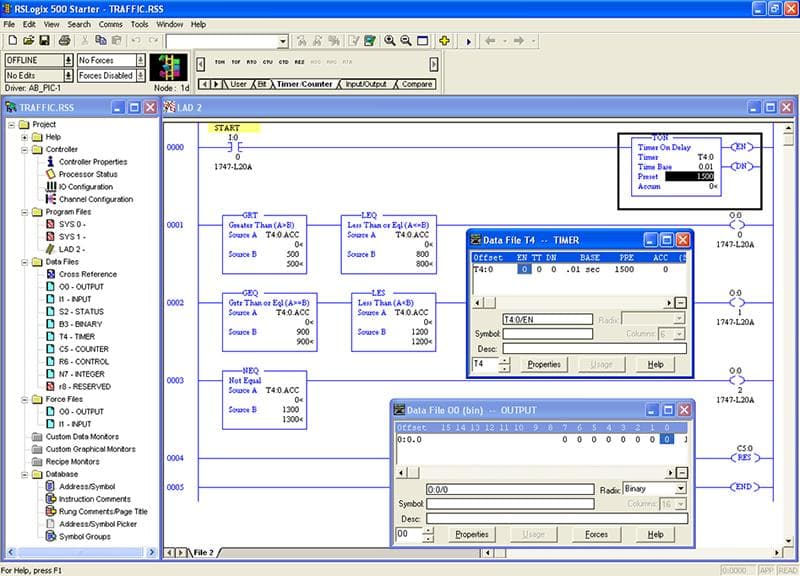

Our design and engineering team is fully familiar and trained on PLC product lines of major OEMs and Industry standard configuration of IEC-61131, to adapt the intended functionalities in PLC solutions as per customer needs of process automation:

- ABB – AC500, AC700F, AC800F, AC800M and AC900F PLCs

- Siemens – S7/300 & 400, S7/1200 and S7/1500 PLCs

- Honeywell – Master Logic ML200 and Control Edge PLCs

- Rockwell – Control Logix 5000 and Compact Logix 5000 PLCs

- Schneider – Modicon PLCs

We have expertise and references of PLC solutions in following industry sectors:

- Plant Auxiliaries and Packages for Oil & Gas, Petrochemicals and Refineries.

- Plant Auxiliaries and Packages for Water Desalination and Power Generation.

- HVAC and District Cooling systems.

- Infrastructure – Tunnels and Highways management & monitoring

- Cement, Paper & Pulp, Food and Beverage Industries.

- Factory Automation and Machine s Controls & Monitoring

- Solid Waste and Sewage Water Treatment Plants.

- Building Management and Data Centers

Key Features

- IIoT-ready PLC integrated with DCS/ SCADA.

- Universal I/O hardware - lead to reduction of spare channels & accessories; improved project schedule, cost and risks.

- Thanks to Universal I/O hardware - Flexible/ scalable design, Efficient project engineering and Reduced spare inventory.

- Life cycle investment protection i.e. new equipment integration, upgrades and migrations

- OPC UA Protocol lead to smooth integration of field devices and ease in configuration

- Fully integrated Cyber Security provides security built in to PLC/ DCS, preserves safety & availability and industrial cyber security solutions and managed services .