Process & Industrial Automation Solutions

Remote Terminal Unit (RTU)

Our offering for RTU (Remote Terminal Unit) packages are based on cutting edge technology from leading OEMs, supporting remote & safe operation, low power consumption, support gas & liquid metering, optimize the production, efficiently maintain the reserve by real-time data monitoring and wide operating temperatures to cover the Process Industries, Infrastructure, Oil & Gas, Mining, Minerals & Metals and Utilities sectors.

Our offered RTU solutions are independent of OEMs or Brands, as we select RTU products based on customer budget, AVL, technical needs, life cycle of asset, future expansions or enhancements and latest trends of technology i.e. HART, Modbus, DNP 3.0, API library, Radio communication, Cyber Security, IIOT, Digitalization and ERP integration.

Our RTU solution design, RTU products from leading OEMs, enclosures & housing and accessories are assembled and tested for quality and intended functions at modern integration facilities in ME and India – this enable customer to be part of review/approval cycle remotely or in-person and obtain desired customized functionalities in cost affective manner.

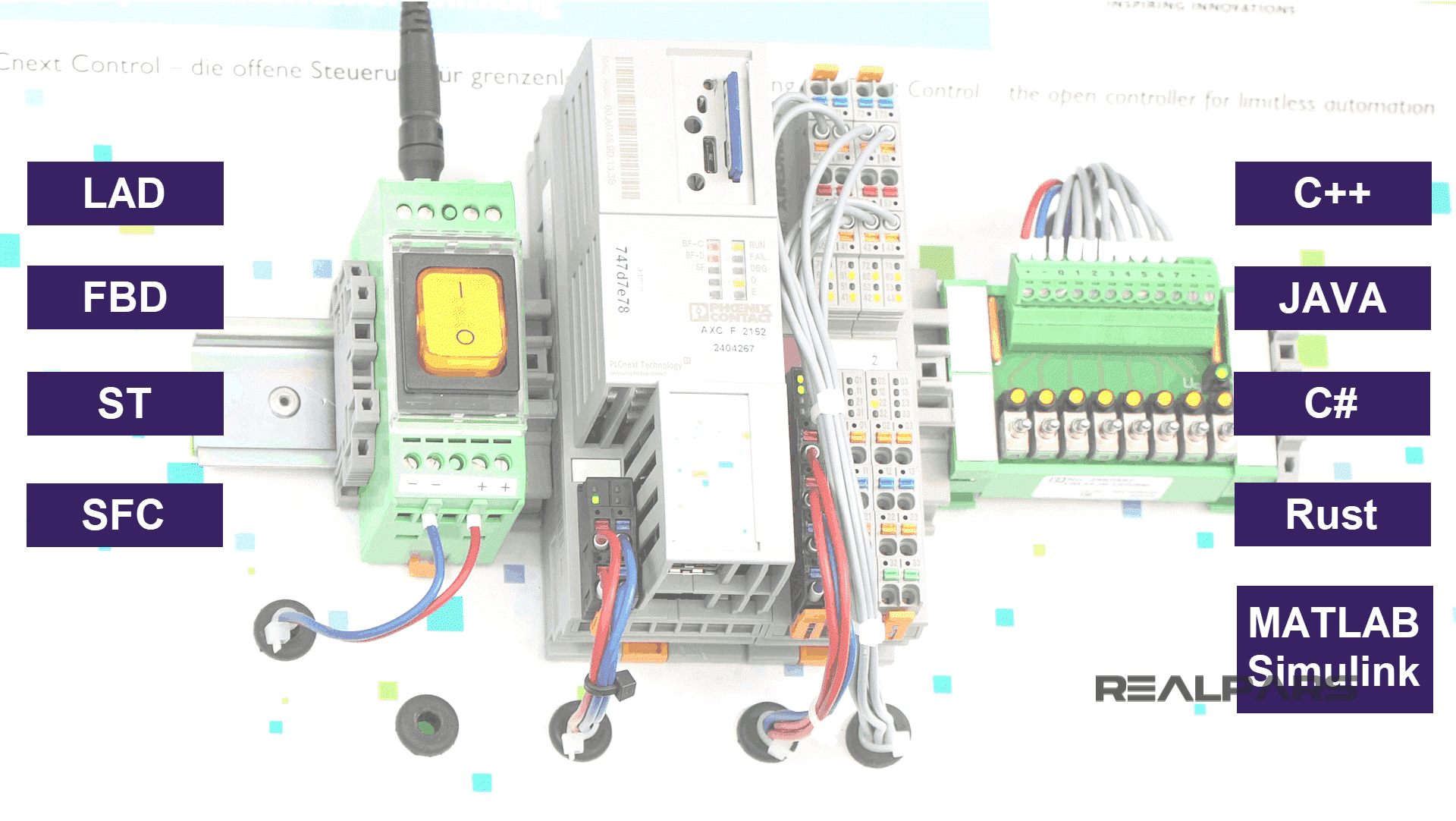

Our design and engineering team is fully familiar and trained on RTU product lines of major OEMs and Industry standard configuration of IEC-61131, to adapt the intended functionalities in RTU solutions as per customer needs of remote supervisory control and monitoring:

- ABB – 500 Series RTUs

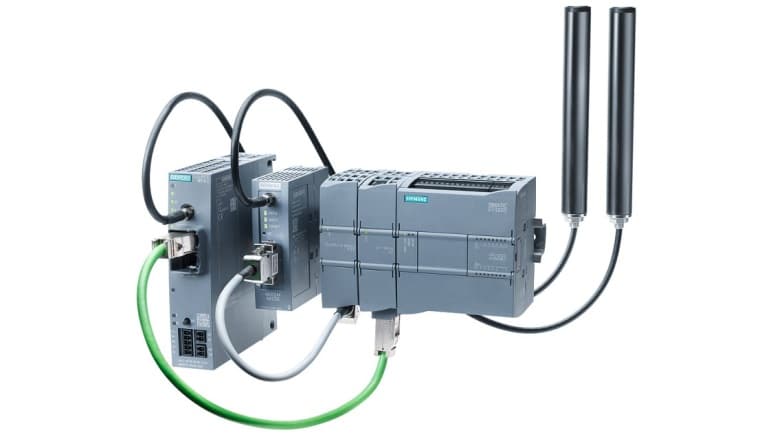

- Siemens – Modular Remote Terminal Units (RTUs) based on S7 series PLCs

- Siemens – Compact SIMATIC RTU3000C family

- Honeywell – Control Edge RTU2020

- Schneider – SCADA Pack Series RTUs

- Phoenix Contact - PLC Next as RTU

We have expertise and references of RTU solutions in following industry sectors:

- Oil & Gas Wellheads

- Water and Power - Transmission & Distribution.

- Infrastructure – Roads, Highways and Tunnels

- Water Irrigation Monitoring

Key Features

- Embedded HART, Modbus, DNP3 – No specialized modules required

- Embedded Cyber Security – Reduced Cyber threats. ISA Secure Compliant

- Redundant Controller – Improved reliability, not an engineered solution

- Integrated HART and Wireless I/Os improves device diagnostics, improves process uptime and reduces capital cost.

- Lowest power consumption of 1.9W with HART I/O, enable savings with smaller solar panels & batteries.

- Enhanced cyber-security with embedded firewall and secure protocols for redundant controller.

- Integrated flow computing for liquid and gas meter runs with support for AGA algorithms and API compliance.

- Exceeds Harsh Environment Specifications: -40ºC to 75ºC and Conformal Coating – G3.

- Easy device add-on on brownfield sites with legacy & new protocols inline with Industry 4.0 requirements.